I have acquired something very cool.

-

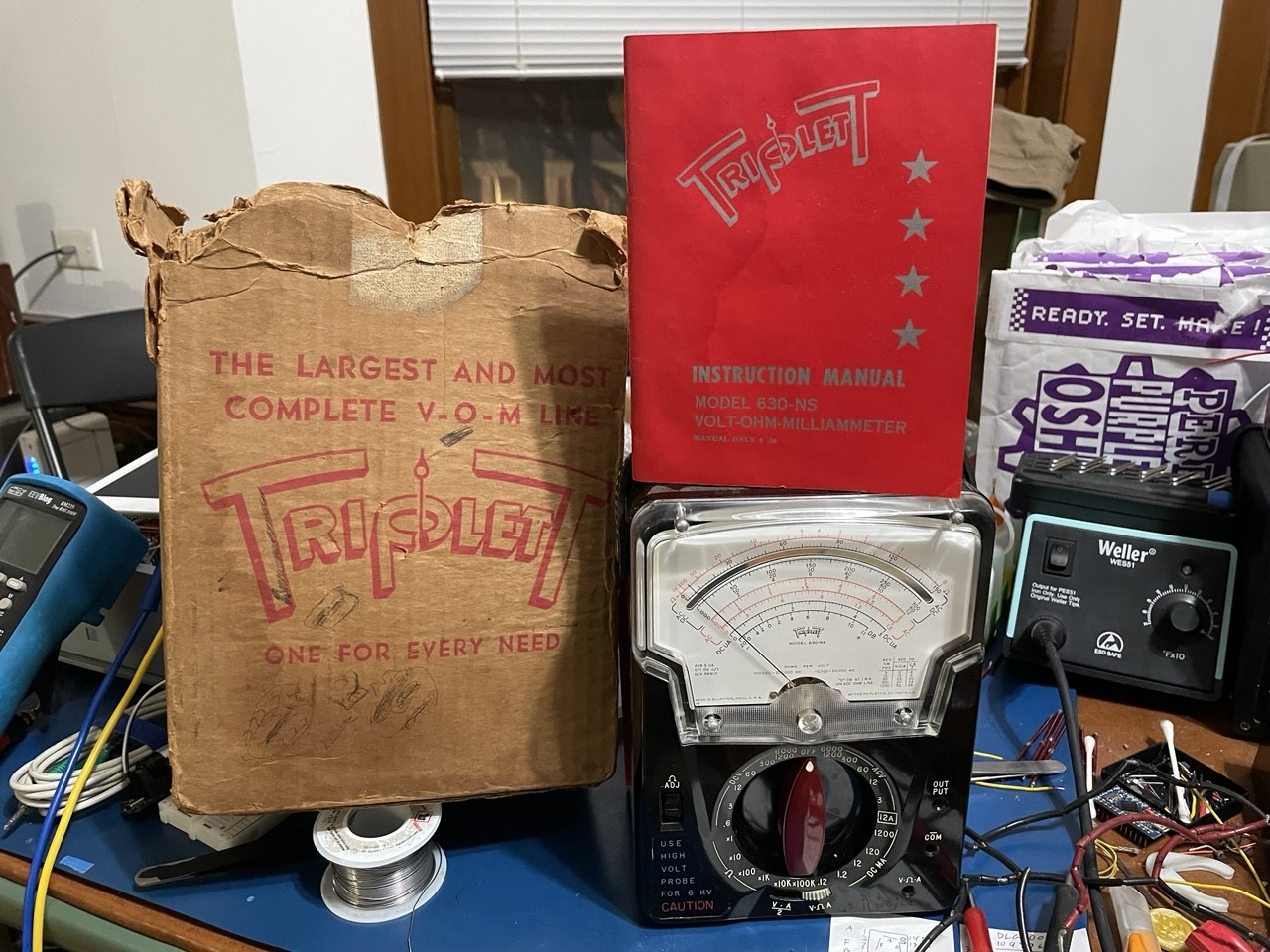

I have acquired something very cool. A friend was buying some stuff on craigslist and the seller offered a discount on further items and forwarded some computer items to me. I got an ATX power supply and a fan, but I also spied THIS. A Triplett 630-NS Volt-Ohm-Milliammeter with the original manual and box!

-

I have acquired something very cool. A friend was buying some stuff on craigslist and the seller offered a discount on further items and forwarded some computer items to me. I got an ATX power supply and a fan, but I also spied THIS. A Triplett 630-NS Volt-Ohm-Milliammeter with the original manual and box!

It’s reportedly not working correctly, but assuming the gauge itself isn’t blown, I think I can fix it. Because this is from a time when tools were meant to be maintained. The manual has a full parts list and schematic.

-

It’s reportedly not working correctly, but assuming the gauge itself isn’t blown, I think I can fix it. Because this is from a time when tools were meant to be maintained. The manual has a full parts list and schematic.

I can’t find a date anywhere, but this manual is definitely older than the one you can find online. It does mention “special germanium diodes” to protect the movement from overloads, but that could still be late 40s. All the diagrams depict tubes.

Unfortunately the probes are knackered. I can rewire them, but the banana jack end is overmolded so it would have to be a splice job.

-

I can’t find a date anywhere, but this manual is definitely older than the one you can find online. It does mention “special germanium diodes” to protect the movement from overloads, but that could still be late 40s. All the diagrams depict tubes.

Unfortunately the probes are knackered. I can rewire them, but the banana jack end is overmolded so it would have to be a splice job.

I suppose let’s start by testing it. The good news is the movement is fine. Voltage is working, though not very accurately. This should be dead on 5V.

The ohms range is non-functional, which I expected. That requires batteries, and I expect to see some alkaline horrors when I open this up.

The milliamps range is… weird. .12 and 1.2 seem to work properly through this 1 megohm resistor, but 12 and 120 are reading the same and very high, like those ranges are connected directly to the movement coil. 1200 is just dead. I’m guessing blown fuse.

The divide by two switch seems to work properly.

-

I suppose let’s start by testing it. The good news is the movement is fine. Voltage is working, though not very accurately. This should be dead on 5V.

The ohms range is non-functional, which I expected. That requires batteries, and I expect to see some alkaline horrors when I open this up.

The milliamps range is… weird. .12 and 1.2 seem to work properly through this 1 megohm resistor, but 12 and 120 are reading the same and very high, like those ranges are connected directly to the movement coil. 1200 is just dead. I’m guessing blown fuse.

The divide by two switch seems to work properly.

It has flat head screws holding it together, accessible down a very long narrow hole. Which means I do not have a screwdriver that can take this apart.

-

It has flat head screws holding it together, accessible down a very long narrow hole. Which means I do not have a screwdriver that can take this apart.

If anyone has an idea of when this is from, I’d love to hear it. This is the manual I found online, which clearly describes a newer version and uses their modern logo. https://chrisgrossman.com/manuals/triplett/Triplett_630NS.pdf

Some interesting differences:

- The old manual shows only tubes, coils, resistors, and capacitors in the example circuit diagrams. The new one shows transistors and diodes.

- The old manual has this kind of sketchy method for measuring capacitance, which is absent in the new one.

- The old manual refers to the batteries by Eveready part numbers, No. 950 and 915. The new manual refers to them as size D and AA.

- The old manual says the movement is protected by “germanium diodes”. In the new manual it’s a “silicon diode network”. -

Testing this a little more, it seems like the .12, 1.2, and 1200mA ranges are measuring fine. That’s good news, as that most likely means there’s no fault in the movement itself.

DC volts is about 5-10% low, but AC is about 25% low.

This whole thing is made out of precision resistors. According to the parts list, most of them are metal film +/-0.5%, and three on the mA ranges are wire wound +/-0.25%. There’s a few carbon composition +/-5% but they’re not in critical locations. These are going to be annoyingly expensive.

Possibly the insulation on the wire wound ones has just gone, and some are shorted through. I wouldn’t expect the metal film ones to degrade but maybe the coatings were not that robust. I also wonder if this is all just a battery corrosion problem.

-

If anyone has an idea of when this is from, I’d love to hear it. This is the manual I found online, which clearly describes a newer version and uses their modern logo. https://chrisgrossman.com/manuals/triplett/Triplett_630NS.pdf

Some interesting differences:

- The old manual shows only tubes, coils, resistors, and capacitors in the example circuit diagrams. The new one shows transistors and diodes.

- The old manual has this kind of sketchy method for measuring capacitance, which is absent in the new one.

- The old manual refers to the batteries by Eveready part numbers, No. 950 and 915. The new manual refers to them as size D and AA.

- The old manual says the movement is protected by “germanium diodes”. In the new manual it’s a “silicon diode network”.Testing this a little more, it seems like the .12, 1.2, and 1200mA ranges are measuring fine. That’s good news, as that most likely means there’s no fault in the movement itself.

DC volts is about 5-10% low, but AC is about 25% low.

-

This whole thing is made out of precision resistors. According to the parts list, most of them are metal film +/-0.5%, and three on the mA ranges are wire wound +/-0.25%. There’s a few carbon composition +/-5% but they’re not in critical locations. These are going to be annoyingly expensive.

Possibly the insulation on the wire wound ones has just gone, and some are shorted through. I wouldn’t expect the metal film ones to degrade but maybe the coatings were not that robust. I also wonder if this is all just a battery corrosion problem.

I got a screwdriver and a good shop to recommend. This is a small local hardware store, one guy there. I ask for a narrow flat blade screwdriver and he shows me what they have on the rack. I find a 3/16” that looks it would work, but it has the usual trapezoidal head. I measure it and it’s almost exactly 1/4”, so I’m not sure it’ll fit.

“You could just grind that off,” he offers.

“Yeah, but I don’t have a grinder.”

“Oh, you can use ours.”

“Really!?”

“Yeah, sure.”

“Then I’ll take it!”

He rings me up, then leads me back to the grinder and lets me loose. Screwdriver worked great.

So if you need some tool help on the north side of Chicago, go to Andersonville Hardware. I’ll definitely be back.

-

R ActivityRelay shared this topic